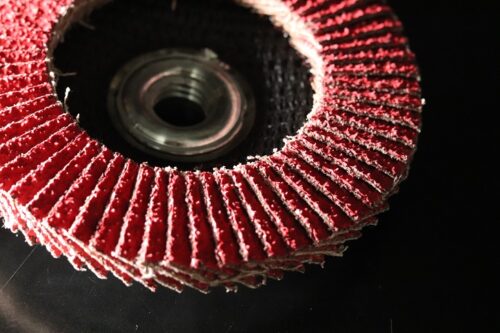

RockRidge flap discs offer versatility allowing the user to grind stock and finish the surface in a single operation. The abrasive-coated flaps are adhered to a rigid backing. The back plate provides stability during operation allowing a cooler cut, less vibration, and a smoother finish. The layered flaps aid in decreasing gouging on the metal being worked on. Flap discs are applicable from stock removal to blending the surface.

RockRidge flap discs are available in either zirconia alumina or ceramic abrasive grains. RockRidge’s flap discs are sold in two different shape styles as well, type 27 or type 29.

Zirconia Alumina

Zirconia alumina grain, on the poly/cotton backing, provides both excellent cut rates and extended product life. Zirconia grain is aggressive and durable, constantly resharpening for long life and consistent finishes. The fiberglass backing is lightweight and high strength.

It is ideal for blending, deburring, cleaning, and stock removal.

The zirconia alumina discs are available in standard or high-density (HD) flap designs.

Ceramic Alumina

Ceramic alumina grain is hard, tough, and sharp. It has a micro-structure that allows the grain to easily resharpen itself during use. This provides the same cut and finish through its extended life span. Ceramic will provide a longer life than other abrasive grains. The poly backing provides less fraying and greater grit retention.

Ceramic flap discs are the best choice for aggressive stock removal, deburring, cleaning, finishing, and blending applications on stainless steel and other high alloys.

The ceramic discs are available in standard flap designs.